There are many kinds of "handles" out there, and if you've ever been to Lowe's, Home Depot or any kitchen design store, you'll know what I'm talking about. There are silver handles, black handles, pewter handles, ones with twists in them, square or round ones, handles with letters and handles with a "rustic" feel. SO MANY HANDLES! But there's more to it than that.

In the industrial handle workd, there are sub-categories of handles that you like to know about, and in this article we're going to discuss the pros and cons of a few of them. Specifically, we're going to talk about Flush handles, Surface Mount Handles, Fixed vs. Drop Handles, and Concealed Handles.

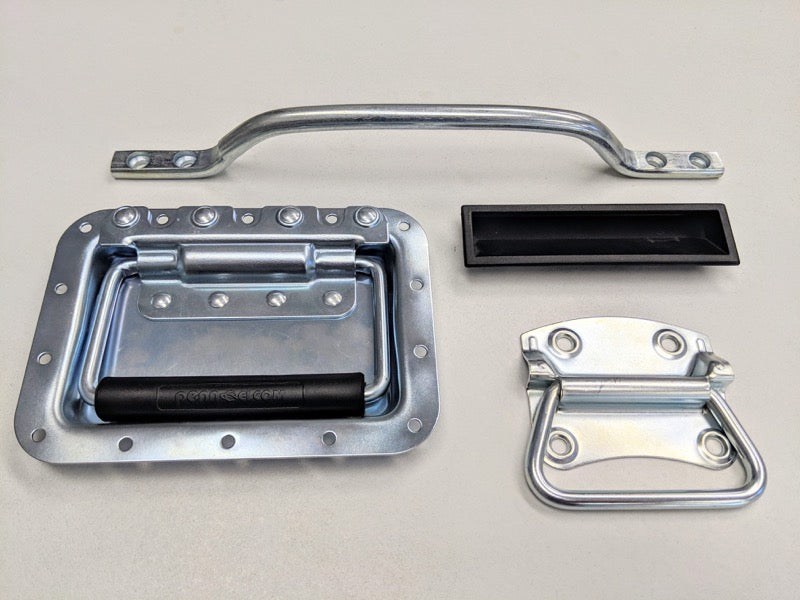

Flush Handles

When your project or application doesn't give you much room for a handle to stick out beyond the front or top of your enclosure, a flush (or "recessed") handle is a good option. They're a bit more work to install because they require a cut-out so they can be recessed into your drawer front or lid, but they require little or no space when not in use. You can find concealed handles in many sizes, some are even just a ring that flips out so you can pull with just one finger. Others (like the one shown in the photo) are designed for a full grip.

Surface Mount Handles

Surface mount handles simply attached to the front or top of your compartment, providing an easy place to grab and open. Surface Mount handles are often the least expensive, require no special cutouts. They're low-tech and robust, and there are literally thousands of variations and dozens of available finishes.

Fixed Handles vs. Drop Handles

Fixed handles have no folding options and they're not articulated in any way. A Drop or "Folding" handle can be folded out of the way, or has a spring to snap it into a "flat" position when not in use.

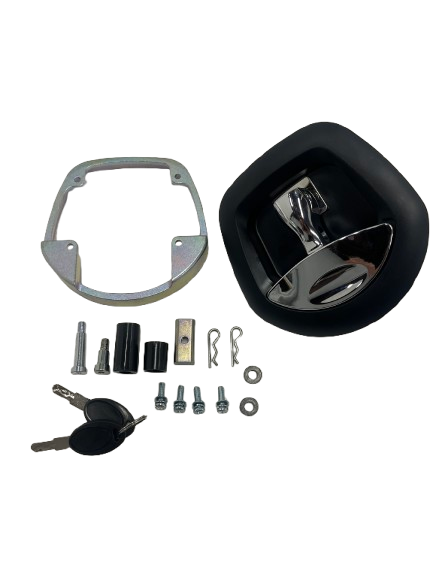

Concealed Handles

Concealed handles fold neatly out of the way when not in use. This gives them a more "decorative" feel, but "decorative" often comes at the cost of strength. Concealed handles are generally made of plastic and are best suited for more light-weight applications.

A Word About Strength

One of the most important (yet overlooked) details when installing handles is the fasteners. The capacity of any handle is limited to the holding force of the fasteners you use. If you want maximum strength, consider using bolts and nuts. If that's not feasible, then use the largest screws that will fit nicely in the mounting holes and make sure that they are of sufficient length to grip properly. Finally, if there are 4 mounting holes, use 4 screws. Don't be cheap on the fasteners!

If you have any questions about which handle is right for you, you're welcome to call us and we'll gladly talk with you about your project to find just the right handles for you.